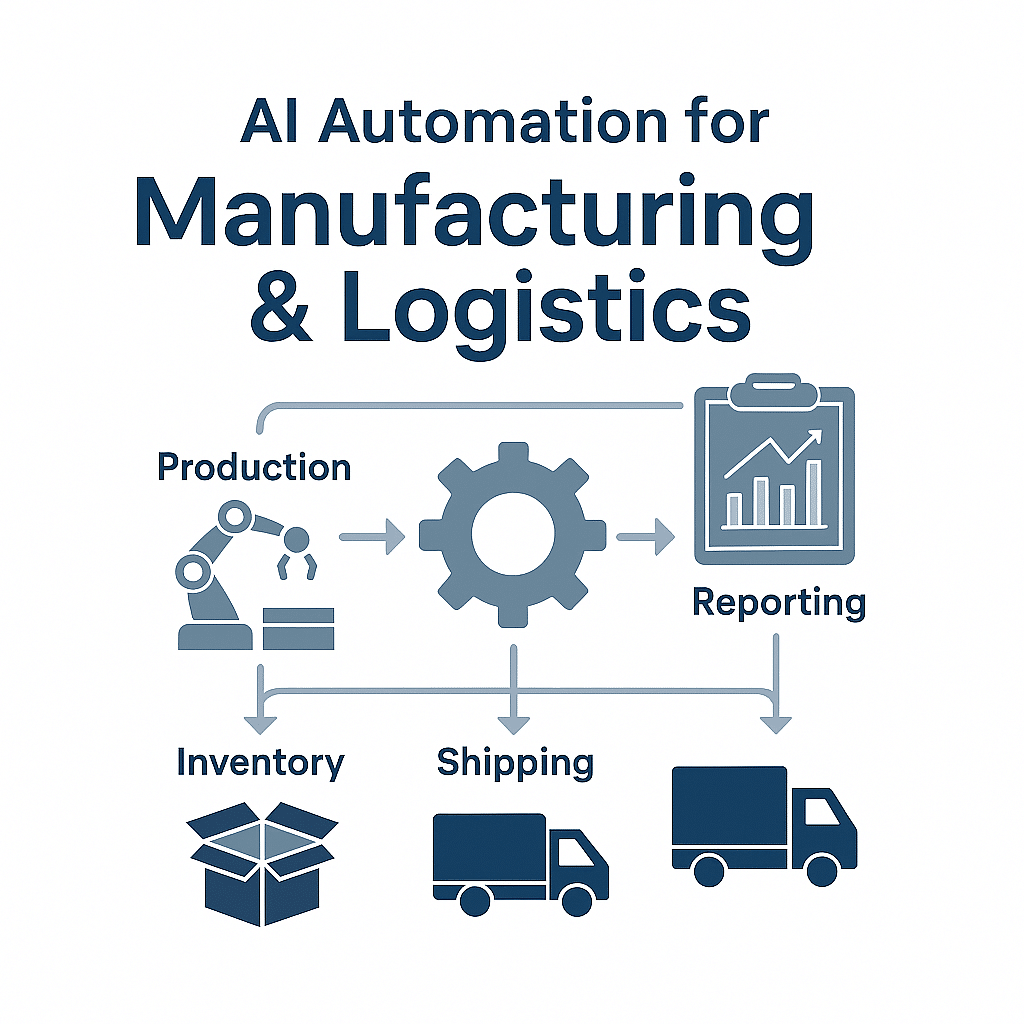

AI Automation for Manufacturing & Logistics

Streamline production, inventory, and supply coordination through integrated automation systems.

Manufacturing and logistics companies rely on precision and timing. Delays, data errors, and manual entry create costly disruptions across production lines and delivery networks. Convex Systems designs automation workflows that connect your production, inventory, and logistics tools into one synchronized ecosystem.

Our systems improve real-time visibility, standardize reporting, and eliminate redundant communication loops — allowing your team to focus on output, not operations.

Where Efficiency Breaks Down

Manual data handling, inconsistent scheduling, and isolated tracking tools create blind spots in manufacturing and logistics.

Automation provides the structure and speed needed to maintain accurate performance across every stage of production and delivery.

Common friction points:

01

Production updates tracked manually in spreadsheets

02

Inventory data not synced between warehouse and CRM

03

Shipping schedules disconnected from customer orders

04

Delayed status reporting across teams or regions

Convex Systems integrates your existing platforms — ERP, logistics trackers, and inventory systems — into unified, measurable automation workflows.

What’s Automated

| Process | Automation | Outcome |

|---|---|---|

| Production Reporting | Auto-sync line data to dashboards and reporting systems | Live performance visibility |

| Inventory Management | Automated stock tracking and reorder alerts | Zero manual counts or missed replenishment |

| Shipping Coordination | Workflow linking warehouse status to logistics partners | Faster and traceable deliveries |

| Quality Assurance | Automated inspections and compliance documentation | Consistent accuracy and reporting |

Automation ensures production, inventory, and delivery teams operate from the same data — minimizing downtime and improving customer reliability.

Example Use Case

Ontario Case:

A manufacturing firm in Guelph implemented Convex Systems automation to monitor production and sync inventory levels in real time. The system reduced manual report generation by 75% and provided management with live dashboards tracking line output and quality metrics.

Alberta Case:

A logistics operator in Calgary automated shipment tracking and vendor notifications. Each shipment update now triggers instant customer alerts, cutting follow-up emails by 90% and improving delivery accuracy across multiple depots.

Result:

Unified data flow across production and logistics created measurable ROI and faster response capability.

Why Manufacturing Automation Works

Manufacturing and logistics rely on repeatable, data-rich workflows.

Automation brings consistency, scalability, and predictive insights — transforming how operations teams handle production, stock, and movement.

Convex Systems develops automation frameworks that adapt to real-world industrial needs: uptime reliability, offline operation, and multi-system integration.

Every build focuses on measurable ROI and long-term maintainability.

Why It Matters

Operational precision defines profitability.

Automation ensures every process — from raw material intake to final shipment — happens on time, within tolerance, and fully tracked.

Convex Systems enables businesses to scale efficiently without adding administrative load — creating visibility, accountability, and continuous improvement.

Measurable Outcomes

| Metric | Typical Improvement |

|---|---|

| Reporting Time | ↓ 70% manual effort |

| Inventory Accuracy | ↑ 98–100% consistency |

| Shipment Coordination | ↑ 2× faster turnaround |

| Operational Downtime | ↓ 30–50% reduction |

All results are measurable within existing ERP or logistics tracking tools — creating clear before-and-after visibility for ROI validation.

Build for Scale

Automation enables continuous improvement.

Convex Systems builds modular workflows that evolve with your production capacity and technology stack — built for uptime, accuracy, and operational resilience.

Start with an AI Readiness Audit

Every automation build begins with a readiness audit.

We identify time-loss points, evaluate system integrations, and provide a step-by-step plan for measurable workflow upgrades.

Fill out the form below and we’ll review your current setup. You’ll receive a detailed proposal within 1–2 business days.

We respond within 24 hours. No automated replies — a real person reviews your request.