Production reporting remains one of the most persistent operational challenges for manufacturing plants in Brampton. Many facilities still rely on handwritten logs, inconsistent shift notes, and manual data entry. These gaps introduce delays, reduce visibility, and complicate root-cause analysis. Supervisors often spend more time interpreting notes than acting on insights.

Brampton manufacturing automation provides an opportunity to replace fragmented reporting habits with structured, reliable, and auditable workflows. The goal is not to remove human judgment but to eliminate the friction caused by inconsistent inputs. AI production reporting automation supports this shift by standardizing how production details, downtime events, and shift summaries are captured and delivered to decision-makers. When AI and orchestration tools are applied together, Brampton plants can strengthen uptime performance, reduce rework, and build a foundation for plant-wide operational clarity.

Why Production Reporting Breaks Down

Traditional reporting processes fail for predictable reasons. Manual data entry introduces unavoidable delays and mistakes. Each operator documents shift activity in a different way, often using their own shorthand or leaving out important context. What one operator considers a minor variance may appear significant to another. These inconsistencies create reporting gaps that disrupt decision-making. Supervisors require accurate data to understand line performance, downtime drivers, and consumption patterns, but manual logs often lack the precision necessary for timely interventions.

Downtime and incident reporting follow the same pattern. Plants may have clear reason codes or formal templates, but in practice, operators interpret instructions differently across shifts. Reporting becomes a matter of interpretation rather than standard procedure. The Incident Tracking Workflow referenced in the brief reinforces this problem: logs are valuable only when categories and descriptions remain consistent. When they vary from operator to operator, reliability decreases and investigations lose clarity.

How GPT Models Improve Data Normalization

AI production reporting automation addresses these issues by enforcing consistency at the point of data capture. GPT models convert handwritten or unstructured notes into structured production events that follow the plant’s defined standards. Shift notes become uniform summaries, production variances are described using recognized terminology, and missing context is flagged before the record enters a reporting system.

Normalization is the key advantage. Operators do not need to change how they write notes; GPT handles translation into structured fields. This supports faster shift handovers and clearer reporting paths. The OpenAI Integration framework is designed for this type of structured extraction. By applying AI directly to operator notes, Brampton plants can maintain reporting quality without requiring every operator to adopt new documentation habits.

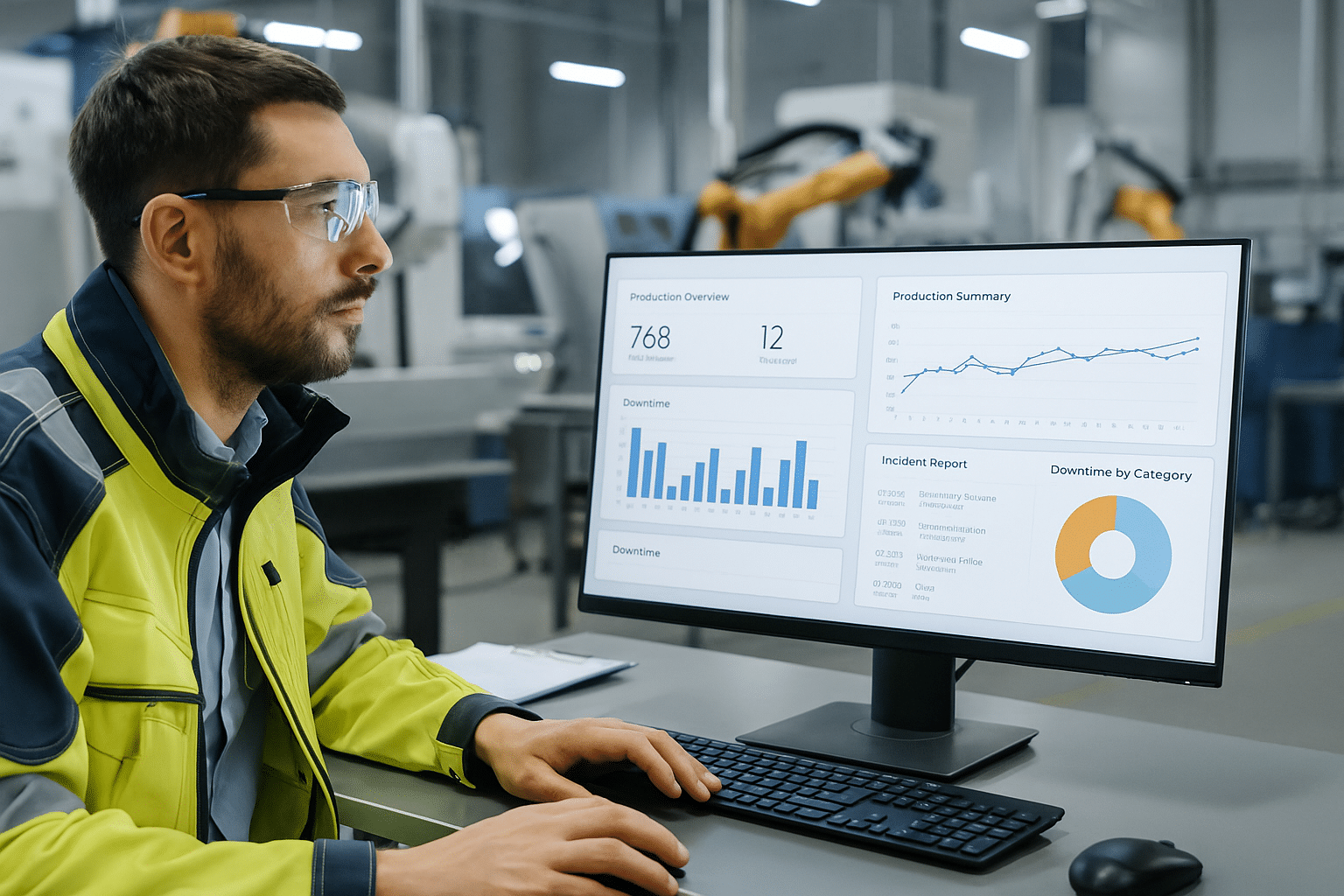

GPT reporting workflows also reduce the cognitive load on supervisors. Instead of scanning long written entries, they receive neatly formatted summaries that include timestamps, categorized events, production totals, and contextual notes. These standardized outputs make trend identification easier and help teams respond to emerging issues with greater speed.

How Automation Orchestrates Reliable Reporting

Once GPT has standardized the data, automation tools such as n8n turn these normalized records into actionable workflows. This is the backbone of Brampton manufacturing automation: structured data moves consistently and reliably through the plant’s reporting ecosystem.

Automation routes records into MES or ERP systems, ensuring that production data aligns across departments. When thresholds are exceeded or variances appear, automated alerts notify supervisors immediately. Logs become digital and standardized, which improves tracking accuracy and reduces the risk of lost or incomplete documentation. Automations are how these orchestrated workflows create reliable audit trails for all reporting activities.

With automation, operational data no longer depends on manual routing. Shift summaries, downtime events, and incident reports flow through the same predictable channels, providing plant managers with consistent inputs for decision-making. This automation is not about reducing human oversight; instead, it reinforces oversight by giving supervisors timely and accurate information.

Example Workflow: Daily Production Summary

A daily production summary often begins with an operator inputting shift notes into a digital form. These notes can be informal or partially structured. GPT then processes the information and converts it into standardized data fields such as production counts, material usage, quality checkpoints, and any deviations from expected output.

n8n validates the structured result. If fields are incomplete or contradictory, the system prompts the operator or supervisor to supply the missing details. Once validated, the output becomes an official production summary. It is stored automatically in a plant-wide repository with a complete audit trail.

This structured workflow gives supervisors confidence that every summary follows the same reporting rules. It eliminates ambiguity from shift transitions and strengthens plant-wide visibility.

Example Workflow: Downtime and Incident Reporting

Downtime reporting requires clarity and consistency, but handwritten logs often include ambiguous descriptions and inconsistent reason codes. Using AI production reporting automation, operators record downtime reasons as they normally would. GPT then normalizes these entries, aligning language with predefined categories, codes, and descriptions.

Automation pushes these structured records into the Incident Tracking Workflow and any connected supervisor channels. n8n ensures that incident details are complete before escalation. When reason codes are missing, unclear, or contradictory, the system prompts operators to correct or complete the entry.

The SOP Generator helps link downtime reporting to established procedures, ensuring that every incident aligns with organizational standards. This creates a consistent method for analyzing recurring downtime patterns and reduces the time required for incident reviews.

Implementation Considerations for Brampton Plants

Implementing Brampton manufacturing automation begins with identifying the highest-friction points in the reporting cycle. Plants should evaluate where data inconsistencies occur most frequently and which teams experience the most difficulty interpreting operator notes. Reviewing existing log formats, data fields, and reporting expectations provides clarity on the changes required for automation.

Plants must decide on the standards for uptime and downtime reporting before deploying AI models. Consistency across teams ensures that GPT workflows have a reliable framework to follow. AI Consulting supports this step by helping plants define workflow architecture, reporting rules, and system integration paths.

Another critical factor is selecting the right automation stack. While n8n is a common choice, plants can use any system capable of handling multi-step routing, conditional logic, and audit trails. The selected system must integrate cleanly with MES, ERP, and incident tracking tools to maximize reporting efficiency.

Finally, plants should communicate clearly with operators and supervisors about the purpose of automation. The shift is not intended to replace judgment but to support more reliable outputs. When teams understand the benefits — clearer reporting, fewer corrections, and improved visibility — adoption becomes much easier.

Conclusion

Manual production reporting exposes Brampton plants to delays, inconsistencies, and reduced visibility. AI production reporting automation creates a new model built on data normalization, structured workflows, and immediate system integration. GPT models transform handwritten notes into standardized entries, while automation orchestrates reliable routing, alerts, and storage.

By adopting these systems, Brampton facilities gain more accurate reporting, quicker insights, and better alignment across operations teams. Production reporting becomes a dependable source of truth rather than a recurring operational burden.

Now is the time for Brampton manufacturers to assess their reporting readiness and determine how AI-driven workflows can strengthen operational reliability across all shifts.